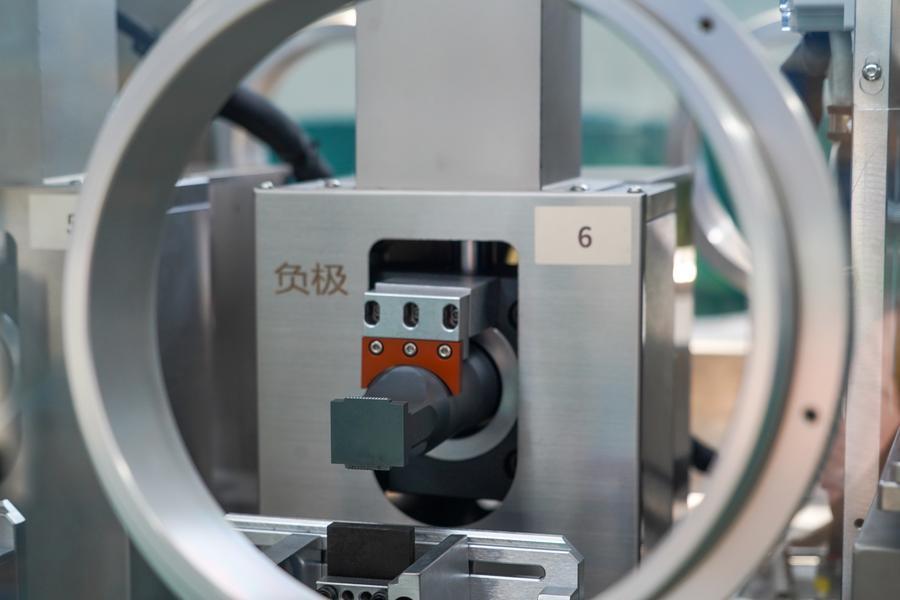

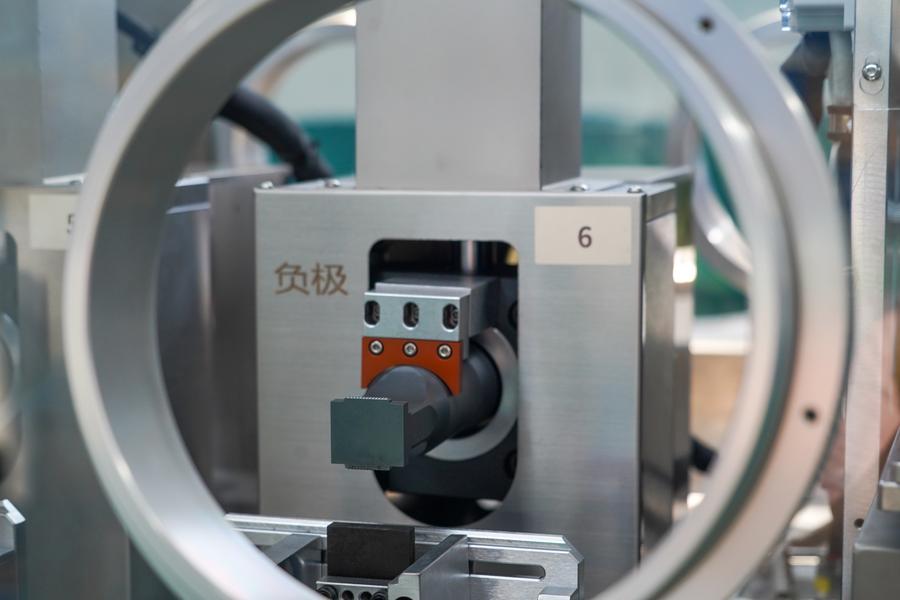

This photo taken on Sept. 2, 2024 shows part of a solid-state lithium metal battery in Yibin, southwest China's Sichuan Province. (Xinhua/Tang Wenhao)

BEIJING, Sept. 25 (Xinhua) -- Chinese authorities recently issued a guideline on promoting high-quality development of energy equipment, proposing to foster the establishment of a battery energy storage equipment system with high safety and high reliability, and develop lithium batteries, sodium batteries, and solid-state batteries with long life, wide temperature range, and low attenuation.

Propelled by the supportive policies, the industrialization process of solid-state batteries is expected to further accelerate.

-- Commercialization still has a way to go

It is learned that solid-state batteries can not only gradually replace existing liquid lithium batteries in their application in new energy vehicles and energy storage, but also have the potential to explore emerging markets such as the low-altitude economy, robotics, and data centers.

A report by Soochow Securities says that according to forecast data, the global shipment of solid-state batteries will reach 614GWh by 2030, and the market size of solid-state batteries in China is expected to continue to expand, reaching 20 billion yuan by 2030.

Since the beginning of this year, there has been a basic consensus on the overall industrialization trend of solid-state batteries that in the next three to five years, China will achieve the fastest progress in the industrialization of solid-state batteries, including the maturity of technology and the completeness of the industrial chain, said Zeng Tao from China Galaxy Securities.

The technological routes of solid-state batteries are diversified, which can be divided into polymers, oxides, sulfides, and halides that have received attention in recent years based on the types of electrolytes.

It is learned that from the perspective of mainstream manufacturers' technology choices, sulfide electrolyte supporters are the majority. However, the current sulfide technology route also faces issues such as the production of flammable hydrogen sulfide gas and the difficulty of preparation, which need to be further addressed.

It can be seen that solid-state batteries still need to overcome multiple technological challenges and achieve cost-effectiveness in order to realize large-scale commercial application, noted Yu Fenghui, a senior researcher at Pangoal, a Beijing-based think tank.

Faced with this situation, the industry needs to increase investment in basic research, promote technological breakthroughs in key materials, and reduce costs and improve production efficiency by establishing standardized production processes and testing methods, Yu added.

-- Listed companies drive industrial development

Multiple listed companies have announced strategic layouts within the solid-state battery industrial chain.

Beijing Easpring Material Technology Co., Ltd. (300073.SZ) has successfully developed sulfide electrolytes with high ionic conductivity, controllable micro-nano particle size, and relative stability in humid environments, as well as chlorine-iodine composite sulfide solid electrolytes with excellent surface wettability, and achieved the capability for mass supply, said a staff member of the company.

Besides, the company's all-solid-state cathode materials, which utilize an ultra-stable, fast-ion conductor modification process, deliver ultra-high capacity and long cycle life within all-solid-state battery systems, and mass shipments on a ten-tonne scale have commenced, added the staff member.

According to a recent announcement of Guangzhou Great Power Energy & Technology Co., Ltd. (300438.SZ), since late August last year, the company has continuously iterated and optimized its solid-state battery technology, with the energy density of its solid-state batteries rising from 280 Wh/kg to 320 Wh/kg.

Jiangxi Ganfeng Lithium Group Co., Ltd. (002460.SZ) stated recently that it has sustained development in the power battery sector, and its solid-state batteries have been trial-fitted in certain vehicle models and have entered mass production, while also being supplied to well-known drone and eVTOL manufacturers.

It is also learned that major cell manufacturers, such as Contemporary Amperex Technology Co., Limited (300750.SZ) and EVE Energy Co., Ltd. (300014.SZ), and leading automakers, including SAIC Motor Corporation Limited (600104.SH) and Chongqing Changan Automobile Company Limited (000625.SZ), are all actively pursuing development in solid-state batteries.

At present, the overall industry is in a phase where technological validation and scaled trial production proceed in parallel, and a breakthrough in commercialization will require ongoing process optimization and cost control, said Guo Tao, deputy director of the China Electronic Commerce Expert Service Center.

(Edited by Gu Shanshan with Xinhua Silk Road, gushanshan.1987@163.com)

A single purchase

A single purchase